| Production line | More |

| Main equipment | More |

| Auxiliary equipment | More |

source:B.START The author:B.START release:2024/1/8 modify:2024/1/8

membership:News click:837

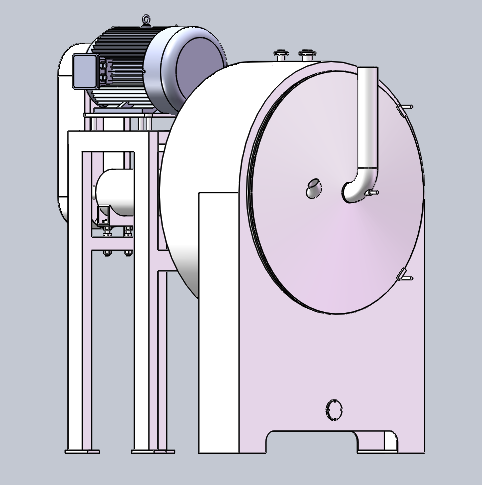

Starch production equipment ---centrifugal sieve

Our centrifugal sieve mainly used for potatoes, cassava, sweet potato, wheat and other grain (rice) slurry-residue separation of the starch processing. The special tailor-made arrangement of the holes on the mesh and sieve could increase the productivity up to 99% and even more .

How to separate slurry and potato residue during starch production process, centrifugal sieve contributes the most.

The crushed slurry is sent to a combination of centrifugal sieve for sieving. During the sieving operation, the slurry enters the centrifugal sieve evenly through the feeding mechanism for screening. Starch and water pass through the sieve holes, and the fine residue is discharged. Water is added for secondary crushing, and the slag liquid is sent to the centrifugal sieve for screening. The starch particles pass through the screen surface , and most of the extremely fine slag is discharged out of the screen and then sent to the centrifugal sieve for screening. At the same time, spray water is used for screening. The fine residue that has been sieved several times is mixed with the coarse residue from the centrifugal screen to become waste residue and is discharged into the waste tank. On a dry basis, the residue content in starch milk should not exceed 8%, while the free starch content in powder residue should not exceed 3%-4%.

Web:www.bosidachina.com

Email: info@bosidachina.com

Copyright © 2012 INNER MONGOLIA BOSIDA TECHNOLOGY CO., LTD, All Rights Reserved

蒙ICP备2021001256号-1 Access statistics:6685620